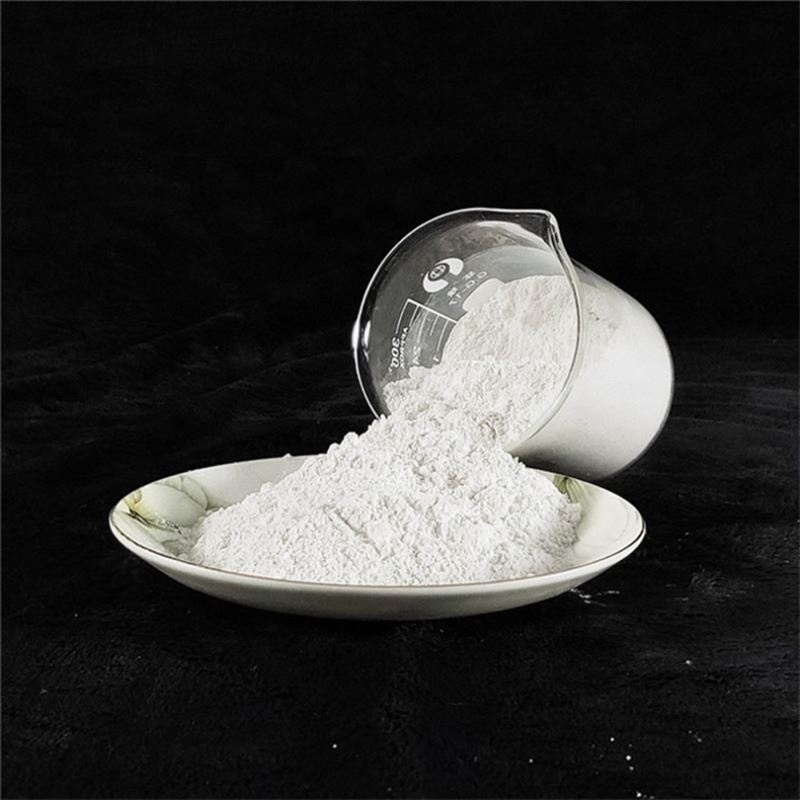

Talc for ceramics (magnesium silicate hydroxide, Mg₃Si₄O₁₀(OH)₂) is a versatile mineral widely used in ceramic production due to its unique chemical and thermal properties. Depending on the ceramic composition and firing conditions, Talc for ceramics influences the body’s mechanical strength, thermal stability, and aesthetic qualities. Below is an expanded discussion of its functions in ceramics.

1. Fluxing Agent – Lowering Firing Temperature

Talc for ceramics acts as a secondary flux in ceramic bodies, particularly in low-fire earthenware and stoneware. When heated, Talc for ceramics decomposes and releases magnesium oxide (MgO), which reacts with silica (SiO₂) and other oxides to form low-melting phases. This promotes early vitrification, reducing the required firing temperature and energy consumption.

Mechanism: Above 850°C,Talc for ceramics breaks down into enstatite (MgSiO₃) and silica, contributing to glass formation.

Application: Useful in fast-fired tiles and artware ceramics where rapid sintering is needed.

2. Thermal Shock Resistance – Cordierite Formation

One of the most critical applications of Talc for ceramics is in cordierite ceramics (2MgO·2Al₂O₃·5SiO₂), which exhibit exceptional thermal shock resistance due to their low thermal expansion.

Reaction Pathway:

Talc + Kaolin + Alumina → Cordierite (at ~1300–1400°C)

This phase is crucial for kiln furniture (shelves, setters) and catalytic converter substrates.

Benefits:

High thermal stability (withstands repeated heating/cooling cycles).

Low dielectric loss, making it useful in insulating ceramics.

3. Thermal Expansion Control

Excessive thermal expansion in ceramics leads to cracking during firing or cooling. Talc powder For Honeycomb ceramic helps reduce the coefficient of thermal expansion (CTE) by forming stable magnesium silicates.

Effect in Porcelain & Stoneware:

Talc powder For Honeycomb ceramic Reduces warping and crazing in glazed tiles and tableware.

Refractory Applications:

In alumina-talc composites, Talc powder For Honeycomb ceramic improves thermal shock resistance.

4. Whiteness & Opacity Enhancement

Talc powder For Honeycomb ceramic is naturally bright white and free of iron impurities, making it valuable in:

Porcelain & Sanitaryware: Talc powder For Honeycomb ceramic Improves brightness without additional whitening agents.

Glazes: Talc powder For Honeycomb ceramic Acts as a magnesium source, contributing to matte or semi-matte finishes.

5. Mechanical Strength & Microstructure Improvement

When fired,talc powder transforms into enstatite (MgSiO₃), a strong crystalline phase that reinforces the ceramic matrix.

Steatite Ceramics (MgSiO₃-based):

talc powder Used in electrical insulators due to high mechanical strength and low dielectric loss.

Reinforcement Mechanism:

Fine talc powder particles fill voids, reducing porosity and increasing density.

6. Reduction of Drying Shrinkage & Warping

Talc powderhas low plasticity, which helps:

Minimize drying cracks in pressed tiles and cast ceramics.

Improve dimensional stability during firing, reducing warping in large flat pieces.