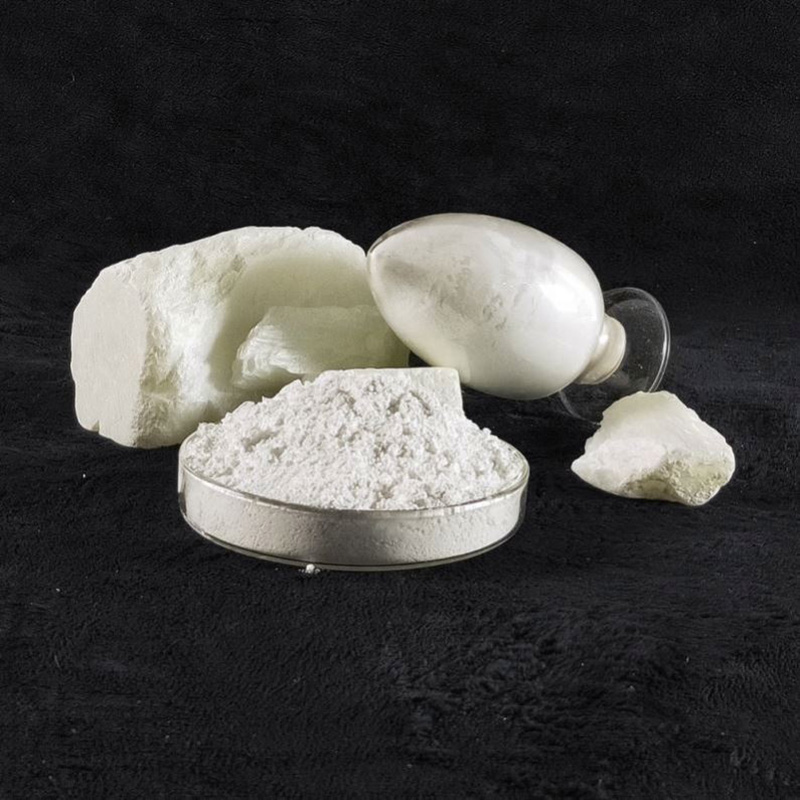

Talc powder For General Plastic (magnesium silicate hydroxide) is a widely used mineral filler in the plastics industry due to its unique properties. When added to polymers, Talc powder For General Plastic modifies mechanical, thermal, and aesthetic characteristics, making it valuable for various applications. Below is an expanded discussion on its effects, advantages, and potential limitations.

1. Mechanical Properties Enhancement

Increased Stiffness & Rigidity

Plastic Grade Talc powder particles act as reinforcing agents, improving the flexural modulus (resistance to bending) of plastics.

Particularly effective in semi-crystalline polymers like polypropylene (PP), where it enhances structural integrity.

Plastic Grade Talc powder Used in automotive parts (e.g., bumpers, door panels) to reduce flexing.

Trade-off: Reduced Impact Strength

While Plastic Grade Talc powder improves stiffness, it can decrease toughness and impact resistance, making the plastic more brittle.

This effect can be mitigated by blending talc powder with elastomers (e.g., EPDM) to balance stiffness and ductility.

2. Thermal Properties Improvement

Higher Heat Deflection Temperature (HDT)

Plastic Grade Talc powder increases the temperature at which a plastic part deforms under load.

For example, unfilled PP may soften at ~60°C, while talc powder-filled PP can withstand 120°C or higher, making it suitable for under-the-hood automotive components.

Reduced Thermal Expansion

Helps minimize warping and dimensional changes in high-temperature environments.

3. Dimensional Stability & Warpage Reduction

Talc Powder Plastic reduces molding shrinkage, ensuring better dimensional accuracy in injection-molded parts.

Critical for thin-walled components and precision parts (e.g., electrical housings, containers).

4. Cost Efficiency & Processing Benefits

Filler Effect: Lower Material Costs

Talc Powder Plastic is cheaper than most polymers, allowing manufacturers to reduce resin usage while maintaining performance.

Improved Processability

Talc Powder Plastic Can enhance melt flow in some cases, aiding injection molding.

However, excessive Talc Powder Plastic loading (>40%) may increase viscosity, requiring processing adjustments.

5. Surface Finish & Aesthetic Qualities

Talc Powder Plastic contributes to a smoother surface in molded parts, reducing defects like sink marks.

Often used in consumer goods (e.g., appliances, furniture) where appearance matters.

6. Barrier Properties (Moisture & Gas Resistance)

Plate-like Talc powder For General Plastic particles can create a tortuous path, slowing down moisture and oxygen diffusion.

Talc powder For General Plastic Useful in food packaging films (when combined with other barrier additives).