III. Challenges and Improvements

Despite its significant advantages, magnesium hydroxide also presents some challenges, primarily:

High Dosage: To achieve the desired flame retardant effect (e.g., UL94 V-0 rating), a very high proportion (up to 60% or more) is typically required. This can negatively impact the mechanical properties of plastics, such as reducing toughness and tensile strength.

Poor Polymer Compatibility: Polar magnesium hydroxide exhibits poor compatibility with non-polar polyolefins and other plastics, easily agglomerating and resulting in uneven dispersion.

To address these issues, surface modification techniques are widely used in industry. Coating magnesium hydroxide powder with coupling agents such as silanes and titanates can significantly improve its dispersibility and compatibility in the plastic matrix, thereby minimizing negative impacts on the material's mechanical properties while maintaining flame retardant efficacy.

IV. Main Application Areas

With its environmentally friendly properties and safety advantages, magnesium hydroxide flame-retardant plastics have demonstrated irreplaceable value in several key areas:

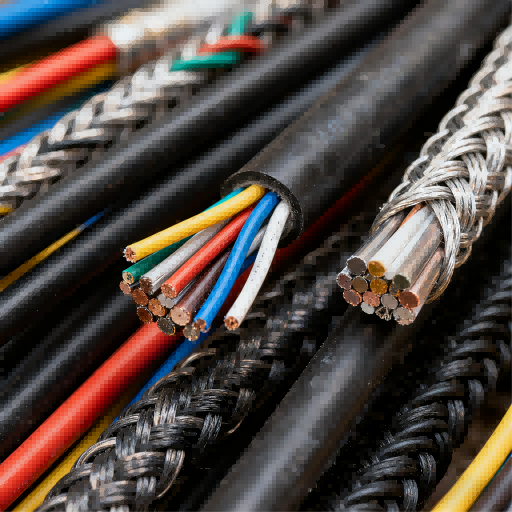

In the wire and cable industry, magnesium hydroxide-modified flame-retardant polyolefin cable materials have become a core material for power transmission and communication optical cables. Its low-smoke and non-toxic characteristics make it particularly suitable for wiring systems in enclosed spaces such as subway tunnels and high-rise buildings, providing valuable time for evacuation in fire scenarios.

In the electronics and electrical appliance industry, from television back panels and washing machine casings to charger housings, magnesium hydroxide flame-retardant plastics meet flame-retardant standards while maintaining good appearance quality and dimensional stability. As electrical products become thinner and lighter, surface-modified, high-filled magnesium hydroxide composite materials are gradually replacing traditional halogen-based flame-retardant materials, becoming a new choice for high-end appliance casings.

In the building materials industry, magnesium hydroxide is widely used in flame-retardant boards, ventilation ducts, and thermal insulation materials. Its decomposition products do not corrode building steel reinforcement and effectively reduce smoke during fires, making it highly recognized in green building evaluation systems.

In the transportation sector, particularly in industries with extremely high safety requirements such as automobiles and high-speed rail, magnesium hydroxide flame-retardant plastics have been successfully applied to interior components such as seat frames, dashboard brackets, and cable trays. Their low smoke density and low toxicity fully meet the stringent standards for rail transit materials, ensuring passenger safety while also satisfying the requirements for environmental friendliness within the train carriages.

Magnesium hydroxide (Mg(OH)₂) primarily functions as a highly efficient and environmentally friendly flame retardant and smoke suppressant in plastics. Through the synergistic effects of heat absorption, dilution, and coverage, it provides reliable fire protection for plastic materials. Despite the challenge of high addition levels, its performance can be optimized through advanced surface modification techniques. In today's pursuit of green, safe, and sustainable development, magnesium hydroxide will undoubtedly continue to hold an important position in the field of flame-retardant plastics, serving as an indispensable "green guardian" for protecting life and property.