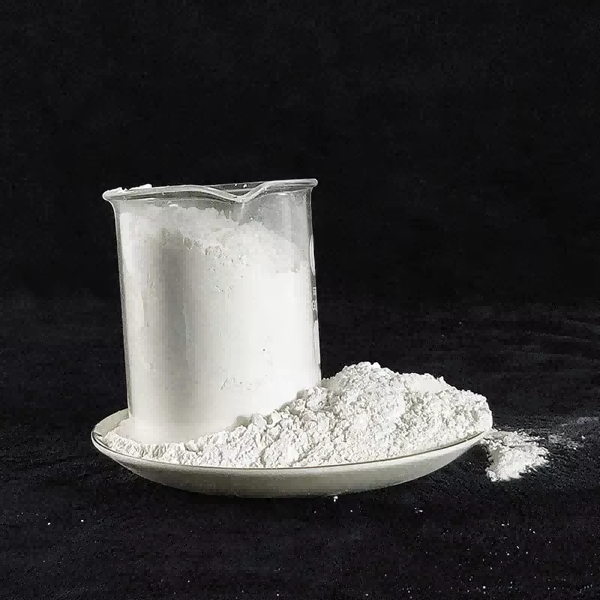

Paint grade talcum powder(talc), a naturally occurring magnesium silicate mineral, plays a crucial role in the paint and coatings industry due to its unique physical and chemical properties. Paint grade talcum powder is widely used as a functional filler and extender, contributing to cost efficiency, durability, and performance enhancement in various types of paints. Below is an expanded explanation of its key applications and advantages.

1. Paint grade talcum powder as a Cost-Effective Extender and Filler

Paints often contain expensive components such as titanium dioxide (TiO₂) for opacity and binders (resins) for adhesion. Paint grade talcum powder helps reduce formulation costs by partially replacing these high-cost ingredients while maintaining acceptable performance.

Volume Enhancement: Paint grade talcum powder increases the bulk of the paint without significantly affecting its properties, allowing manufacturers to produce more paint at a lower cost.

Pigment Spacing Effect: Paint grade talcum powder's plate-like structure helps distribute TiO₂ particles more efficiently, improving opacity and hiding power even at reduced TiO₂ levels.

2. Improving Paint Application and Workability

The lamellar (plate-like) structure of Talc Powder for industrial paints contributes to smoother application and better film formation.

Brushability & Spreadability: Talc Powder for industrial paints reduces drag during brushing or rolling, making the paint easier to apply.

Anti-Sagging Properties: In vertical applications (e.g., walls), Talc Powder for industrial paints helps prevent dripping or sagging by increasing thixotropy (a paint’s ability to resist flow under shear stress).

Reduced Settling: Talc Powder for industrial paints’s fine particles improve suspension, preventing fillers and pigments from settling at the bottom of the can.

3. Enhancing Paint Durability and Performance

Paint grade talcum powder improves several critical performance aspects of paint:

A. Scrub and Wear Resistance

In interior wall paints, Talc for architectural coatings enhances scrub resistance, allowing the paint to withstand repeated cleaning without wearing off.

It reinforces the paint film, making it more resistant to abrasion and mechanical damage.

B. Crack Resistance & Flexibility

The platy Talc Powder for industrial paints particles act as micro-reinforcements, reducing brittleness and preventing cracking as the paint dries and ages.

This is particularly useful in exterior paints, where temperature fluctuations and substrate movement can cause stress.

C. Moisture & Corrosion Resistance

Talc for architectural coatings’s hydrophobic nature reduces water absorption, making it useful in exterior coatings and primers where moisture resistance is crucial.

In industrial and anti-corrosive paints, Talc for architectural coatings helps block moisture penetration, protecting metal substrates from rust.

4. Optical Properties: Sheen Control and Gloss Reduction

Talc for architectural coatings influences the light-reflecting properties of paint:

Matting Effect: Talc for architectural coatings scatters light, reducing gloss and creating flat or low-sheen finishes, which are desirable for interior wall paints.

Smooth Surface Finish: Unlike gritty fillers (e.g., calcium carbonate), talc provides a softer, more uniform texture in the dried film.

5. Stability and Suspension in Paint Formulations

Prevents Hard Settling: Talc for architectural coatings helps maintain a stable dispersion of pigments and fillers, reducing the need for excessive stirring before use.

Improves Shelf Life: By minimizing sedimentation, talc extends the storage stability of paint.