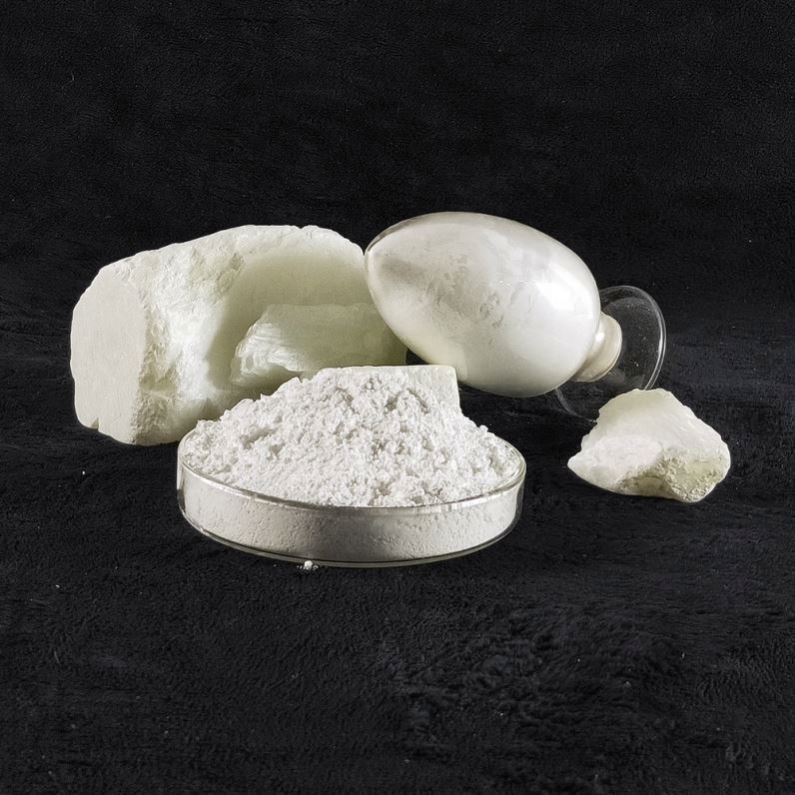

Talc powder(magnesium silicate hydroxide) is a widely used functional filler in the coatings industry due to its unique physical and chemical properties. Its lamellar (plate-like) structure, chemical inertness, and cost-effectiveness make it a valuable additive in various coating formulations, including architectural paints, industrial coatings, and specialty finishes. Below is an expanded discussion on how Paint grade talc powder enhances coating performance and its key applications.

1. Role of Talc powder as an Extender and Filler

Paint grade talc powder serves as an efficient extender pigment, reducing the reliance on expensive primary pigments like titanium dioxide (TiO₂) while maintaining film integrity.

Opacification & Coverage: Although less refractive than TiO₂, Paint grade talc powder improves opacity by optimizing light scattering in the coating matrix.

Pigment Spacing Effect: Its plate-like structure helps disperse TiO₂ particles more effectively, enhancing hiding power.

Volume Solids Adjustment: Paint grade talc powder increases the solid content of coatings without significantly altering viscosity, improving application efficiency.

2. Enhanced Mechanical and Durability Properties

Paint grade talc powder reinforces the coating film, improving its structural integrity and resistance to external stresses.

Abrasion & Scratch Resistance

The hardness and lamellar structure of Talc Powder for industrial paints particles create a reinforced network, making coatings more durable in high-traffic areas (e.g., industrial flooring, automotive underbody coatings).

Flexibility & Crack Resistance

Talc Powder for industrial paints’s platy particles distribute stress more evenly, reducing brittleness and preventing cracking in exterior paints exposed to temperature fluctuations.

Chemical & Corrosion Resistance

Due to its inert nature, Talc Powder for industrial paints improves resistance to acids, alkalis, and salt spray, making it useful in marine coatings and protective industrial paints.

3. Improved Rheology and Application Performance

Talc Powder for industrial paints influences the flow and stability of liquid coatings, ensuring better workability.

Thixotropic Control: Helps prevent sagging in thick films (e.g., textured coatings, heavy-duty primers).

Settling Prevention: The platelet structure slows pigment settling, improving shelf life.

Brushability & Sprayability: Optimizes viscosity for smooth application without dripping or streaking.

4. Barrier Properties for Protective Coatings

Talc for architectural coatings’s lamellar particles align parallel to the substrate, creating a tortuous path that impedes moisture, oxygen, and corrosive agents.

Moisture Resistance: Talc for architectural coatings Reduces water permeability in exterior wood and metal coatings.

Anti-Corrosion Performance: Talc for architectural coatings Used in primers for pipelines, ship hulls, and automotive components.

5. Surface Finish and Aesthetic Modifications

Depending on particle size and shape, Talc for architectural coatings can adjust the coating’s texture and gloss.

Smooth, High-Gloss Finishes: Ultra-fine Talc for architectural coatings (1–5 µm) reduces surface roughness, enhancing gloss in decorative paints.

Matte & Textured Effects: Coarser grades (10–50 µm) are used in stone-effect coatings and anti-slip surfaces.

6. Cost Optimization in Coating Formulations

Paint grade talc powderis a low-cost alternative to many functional fillers (e.g., silica, calcium carbonate) and can partially replace TiO₂ without compromising performance.

Paint grade talc powder Reduces formulation costs while maintaining film strength and durability.

Paint grade talc powder Improves processability in powder coatings by enhancing flow and reducing clumping.