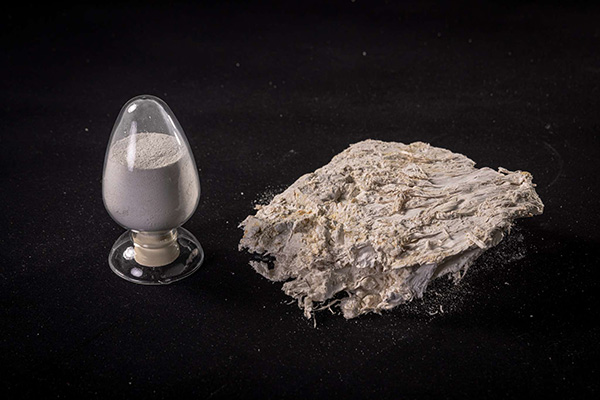

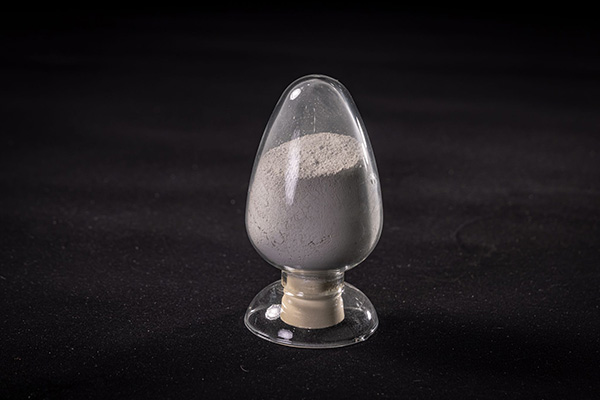

Mag Hydroxide For Flue Gas Desulfurization

1.Magnesium Hydroxide For Heavy metal removal reacts rapidly with SO₂ to form magnesium sulfite (MgSO₃) or magnesium sulfate (MgSO₄), with a desulfurization efficiency of over 90%, making it particularly suitable for the treatment of medium and low sulfur flue gas.

2.Compared with the limestone method, Non-corrosive Magnesium Hydroxide has a higher solubility, requires a smaller volume of absorption tower, and has no risk of gypsum scaling, reducing equipment clogging and maintenance costs.

3.Non-corrosive Magnesium Hydroxide can be used in wet (spray tower) and semi-dry (spray drying) desulfurization processes, and can also be combined with limestone to enhance the performance of traditional FGD systems.

4.Non-corrosive Magnesium Hydroxide generates soluble magnesium salt (MgSO₄), without solid waste residue, which can be directly discharged or recycled (such as for fertilizer preparation), without secondary pollution.

5.Non-corrosive Magnesium Hydroxide Low energy consumption, less equipment investment, long service life, and better economic performance in long-term operation