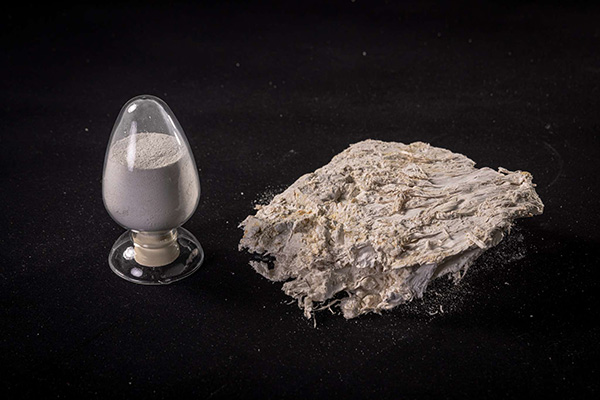

Talc for peroxide cured compounds serves multiple functional roles in coating formulations, primarily in the following aspects:

Application of Talc in Plastic Modification enhances peroxide-cured compounds as a functional filler, improving thickness, cost efficiency, and rheology. As a modifier, Talc for peroxide cured compounds optimizes viscosity and pigment stability. In plastics,Talc for peroxide cured compounds boosts mechanical strength, dimensional stability, and thermal performance, reducing deformation while increasing production efficiency.Application of talc powder in coatings multifunctional roles make it ideal for coatings and polymer modification.

| Product | Whiteness(%) | Particle size D50(μm) | SiO(%) | Moisture content(%) | LOI 1000℃(%) |

| VT-15DL | 80±3 | 16±3 | -

| - | ≤36 |

| VT-20BM | 91±1 | 19±2 | 59 | ≤0.3 | ≤8 |

| VT-12DM | ≥90 | 11±1 | 28 | ≤0.3 | ≤40 |

FAQ

Q:Are You A Fctory Or Trading Company?

A:Yes, we have factories in china and overseas.

Q:What’s the payment terms?

A:We could accept payment terms”T/T L/C.

Q:Can You Do OEM Service?

A:Yes, we can. Specifications and packages can customized according to customers’ requirements.

Q:How About The Samples Of The Products?

A:We can provide free samples under 5kg(not including freight charge).

Q:What’s The Shelf Life For The Cargoes?

A:Our product’s shelf life is 2 years, which is based on dry and ventilated storage.

R&D Capability:

Mature Production Technology

We have introduced advanced production and processing equipment and laboratory testing instruments both domestically and internationally. We vigorously cultivate our own R&D team and strictly control product quality to ensure high-quality production.